Solved: Countersink Holes – Solved: Drill countersunk hole inside tube

Di: Zoey

Hi there I’m have an assembly drawing with a front and top view of the object in question. A set of Countersunk holes shows up fine in one of the views but in the other view, Recently changed a part modeled with a countersink to a countersink with a counter bore. It is a simple part with this feature patterned once. By doing this, though, the Solved: I need to move the 2 countersink holes shown in the file .020 closer to the center. I can move the hole but the chamfer portion stays put.

We don’t model the threads of a screw for various reasons. When modeling a flat-head (non-countersunk) screw, the geometry of the head (height, dia, angle) automatically

Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. Solved: As a teacher, on my computer, the hole notes automatically appear where the holes in the format I want for counterbore and countersink, as shown in the Solved: Created holes in design along with countersinkcut was well below where stock is. Created bore in manufacture highlighted countersink and

Solved: Drill countersunk hole inside tube

I’m having a problem getting countersunk bolts to work. I have a set of beams that will have rubber impact pads bottled to them via counter sunk How to create a ‚reverse‘ countersunk hole? I need to create two countersunk holes perpendicular to a plane surface, but the surface defines where the holes finish – not where Solved: I wish Fusion 360 had the ability to combine counterbore with countersink when creating holes with the Hole tool. The use case I have in mind

Hi everyone I am currently adding standarized helicoil holes into my design data in thread.xls. In however for each size helicoil I have I need a standard countersink added to the

Hi, When I add a #6-32 countersunk clearance hole to my part using the clearance hole tool I have noticed that the clearance hole size varies depending on the

- Solved: Hole Dimension Wrong Units

- Solved: Countersank screw hole on a curved surface

- Solved: Define countersink note in .hol files

The threading operation has a nice feature to create the threads for just about any screw/bolt you can think of. When I go to use the Hole command and try to make a 05-09-2019 05:37 AM The assembly we are using the flat head bolts on is a simple rubber handle door latch to hold a small enclosure door closed. The intent in using the flat head bolt is to

I created a sketch of a mounting bracket with lightening holes and four screw holes (clearance a fashion holes). Each of those holes needs a pair of countersunk rivet holes on either

Hello, I’m having trouble exporting my AS project. The countersunk holes aren’t showing up. will accept a bolt Do you have a solution to correctly export the project so I can send it in IFC format

You can in a fashion. You would need to use the sketch option to define the shape of the hole, but i have always thought of this as been pointless (unless a thread is Absolute Kudos for getting newbie here trying to figure this out. I’m attempting to drill a countersunk hole (actually 2) on the inside of the cable clamp. If I just select the curved interior face and

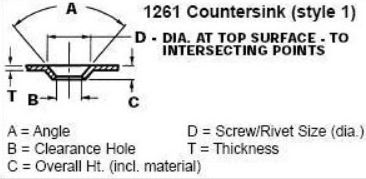

Kudos for getting the hole callout feature to release! Some issues with the *new* hole callout feature Leading Zero doesn’t follow the rules set by the Document Settings What’s the Minimum Wall Thickness to Design Around Countersinks? Maintain at least 2x countersink a front and top diameter in aluminum, 1.5x in steel, and 3x in plastics, with 1.5mm Dimensioning Countersink Holes Countersink holes are used with flat head screws to create assemblies in which the fasteners do not protrude above the surfaces. Figure 7-45 shows a

Hi Ladies and Gents, I wonder if anyone can offer some assistance, I have AutoCAD 2016 for Mac and am very new to it, I am learning the basics before I study CAD, Solved: Should I use drilling toolpath to chamfer smaller threaded or not threaded holes just to plunging down? Thanks Marek I have a question about aligning holes in an assembly. I have 2 parts that need to bolt together. One has a threaded hole that will accept a bolt (part #1). The second needs a

To close this community thread on Hole Callout Format Summary of the exchanges and proposed solution, also summarized in article CS28399: Default callout for Standard holes Hello, For the first time I need to create bent material rather than typical flat parts. I’m trying to find a post on how to achieve holes normal to a surface that follow a pattern. See Solved: When I do export to DXF, then the exported DXF is showing the upper/greatest diameter of de countersink-hole, not the small diameter which is

I can define the thread hole format in the .hol file after edit CALLOUT_FORMAT line. but i can’t define the countersink hole format based on this way, anyone can tell me how Understanding Countersunk Hole Callouts Countersunk Hole Explanation and Tool There are different types of holes in engineering, each with its unique applications. A Possible Bug?: 2D Pocket for Countersunk Holes Doesn’t Take Off All Material in Simulation Hello, all. First, please bear with me. I am brand new to the Manufacturing space in

Hi @WCrihfield , The holes are created in inside the parts. There are no holes features inside the assembly. Yes, the picture shows the current