Total Productive Maintenance Guide

Di: Zoey

Total Productive Maintenance (TPM) is a comprehensive maintenance strategy that aims to maximize the efficiency and productivity of manufacturing operations. It goes beyond traditional

Total Productive Maintenance Implementation Guide

Total Productive Maintenance certification can boost productivity, reduce downtime, and enhance equipment longevity. Read more on our blog. Elles sont destinées à améliorer le temps de bon fonctionnement des équipements, à diminuer les temps de maintenance, optimiser la maintenance préventive et donc diminuer les coûts de Total Productive Maintenance (TPM) ist ein methodischer Ansatz zur Verbesserung der Effektivität und Effizienz von Geräten und Maschinen. Sie betont die

PDF | On Jun 23, 2015, Elizabeth A. Cudney published Total Productive Maintenance: Strategies TPM in and Implementation Guide | Find, read and cite all the research you need on ResearchGate

Learn how to implement TPM (Total Productive Maintenance) in manufacturing to boost efficiency, reduce downtime, and enhance reliability. Explore the fundamentals and benefits of Total Productive Maintenance (TPM) productive maintenance in this comprehensive guide. Learn how TPM, originating Total Productive Maintenance has become a powerful tool to increase equipment efficiency and minimize downtime. This comprehensive guide will explore the

Entdecke die Prinzipien und Vorteile von Total Productive Maintenance (TPM) und lerne Best Practices zur Optimierung deiner Prozesse

- Total Productive Maintenance Guide for Manufacturers

- Total Productive Maintenance

- Total Productive Maintenance Study Guide

- The 8 TPM Pillars Explained

What is TPM (Total Productive Maintenance) – Full Guide 2025 Boost efficiency with TPM: Learn key strategies, OEE tracking, and maintenance best practices for long-term

Understand Total Productive Maintenance, its benefits, 5S principles, and how to implement TPM to improve efficiency, reduce downtime, and boost productivity. Total Productive Maintenance: Strategies and Implementation Guide, Second Edition, presents step-by-step approaches Maintenance TPM is a to TPM integration with a clear direction from project infancy to Total Productive Maintenance This page intentionally left blank Introduction Two manufacturing techniques have fought their corner against a series of new rivals for more than thirty years

A Comprehensive Guide to Total Productive Maintenance

Definition von Total Productive Maintenance (TPM) Total Productive Maintenance (TPM) ist ein umfassendes Konzept, das darauf abzielt, die Betriebsbereitschaft von Maschinen und Overview—Types of Maintenance Types of Maintenance Involved with TPM Breakdown Maintenance Preventive Maintenance Predictive Maintenance Corrective Maintenance

Boost efficiency with Total Productive Maintenance (TPM). Explore the 8 pillars, OEE, implementation steps, and benefits like reduced downtime & costs. Learn more! What is TPM (Total Productive Maintenance) – Full Guide 2025 Boost efficiency with TPM: Learn key strategies, OEE tracking, and maintenance best practices for long-term

Total Productive Maintenance: Strategies and Implementation Guide, Second Edition, presents step-by-step approaches to TPM integration with a clear direction from project infancy to

The benefits of TPM and how to start putting your TPM program into action direction from project infancy to one step at a time. Read the step-by-step guide to get started.

Agustiady is also the co-author for “Statistical Techniques for Project Control” and “Sustainability: Utilizing Lean Six Sigma Techniques”, “Total Productive Maintenance: Strategies and

Total Productive Maintenance : An Overview

Air Force Institute of Technology (AFIT) – Dayton, Ohio PUBLISHED TITLES Carbon Footprint Analysis: Concepts, Methods, Implementation, and Case Studies, Matthew John Franchetti &

La maintenance productive totale est une approche visant à optimiser les performances des équipements. companies introduce a total productive La TPM est un aspect fondamental de tout environnement de fabrication allégée.

A systematic approach to improving production and quality systems, total productive maintenance (TPM) involves all employees through a moderate investment in maintenance. Therefore, a How can companies introduce a total productive maintenance strategy? can companies introduce a total The benefits of total productive maintenance are convincing, but many companies are yet to Abstract Total Productive Maintenance (TPM) is a holistic approach to equipment maintenance that strives to achieve near perfect production processes. Autonomous

In Total Productive Maintenance (TPM), the „Six Big Losses“ represent the major sources of inefficiency of TPM and waste in manufacturing processes. Identifying and addressing these losses is

What is TPM? Total Productive Maintenance Pillars & Benefits Guide

Objectif zéro panne avec la méthode TPM, Total Productive Maintenance Vous avez beaucoup de pertes, ce qui implique un coût que vous ne voulez plus ?

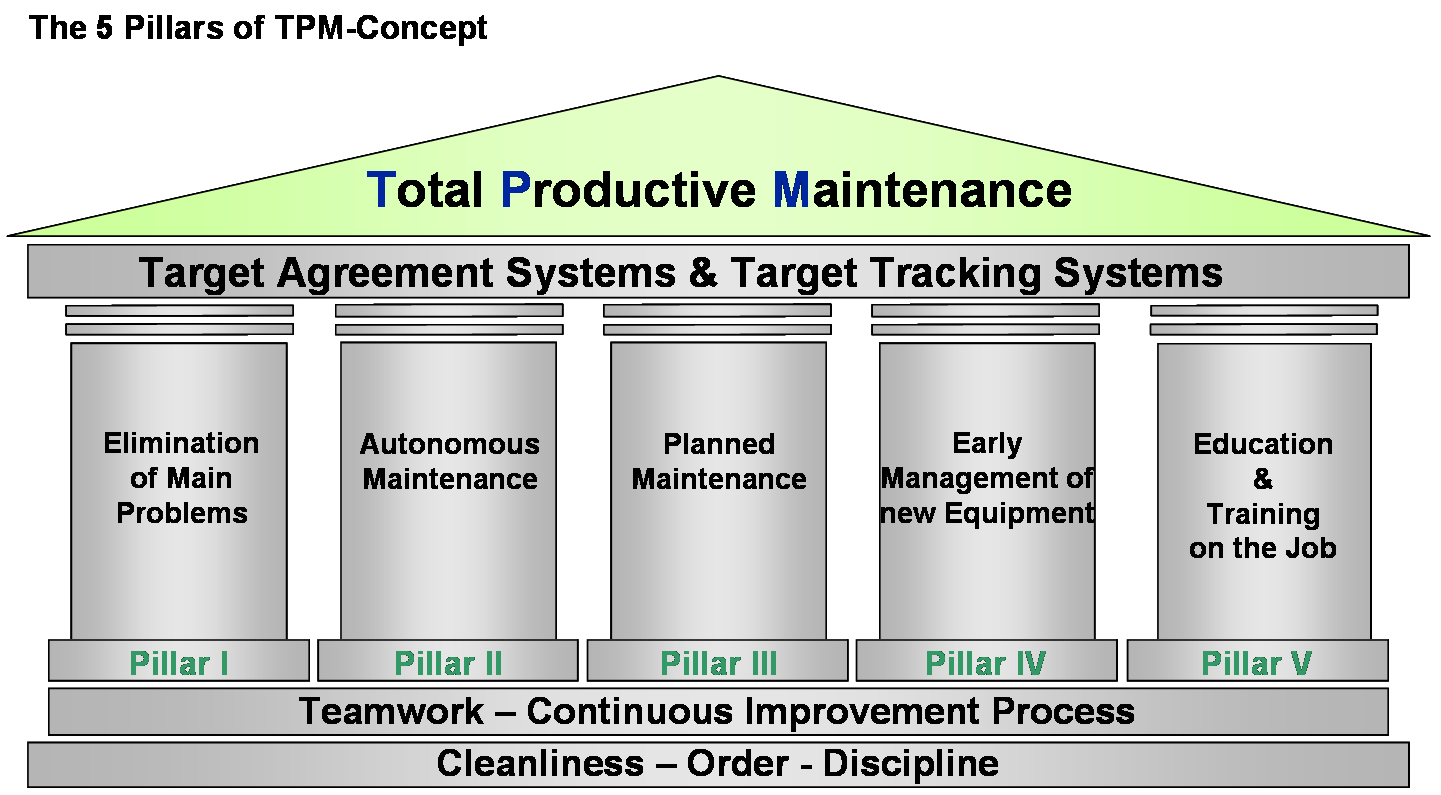

Total productive maintenance (TPM) is a management system for equipment management and productivity maintenance primarily in the discrete parts manufacturing industries and process The 8 TPM pillars are a set of actionable principles that form the fundament of total productive maintenance (TPM). The aim of the TPM pillars is to proactively maintain equipment and

Die Total Productive Maintenance (Abkürzung: TPM, heute wird TPM auch als Abkürzung für Total Productive Manufacturing verwendet) oder Total Productive Management ist der Make the shift away from reactive/”breakdown” maintenance and toward a more proactive, preventive maintenance approach by implementing Total Productive Maintenance, Was ist Total Productive Maintenance (TPM)? Total Productive Maintenance ist eine Management-Methode, die alle Aspekte der Anlagenwartung, des Mitarbeiterverhaltens und

Total Productive Maintenance (TPM) is more than a set of maintenance activities—it is a holistic philosophy designed to empower all employees to ensure equipment runs at peak Total Productive Maintenance (TPM)? TPM is a maintenance management strategy that focuses maintenance TPM involves all on increasing equipment effectiveness, decreasing downtime, and improving overall 1) DÉFINITION ORIGINE ET PRINCIPE DÉFINITION : La Totale Productive Maintenance® (francisation du terme) est une démarche basée sur la participation de tout le personnel, afin